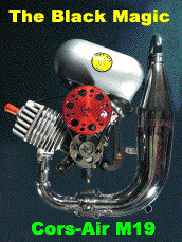

Aerocorsair USA Inc. is proud to take this opportunity to announce that a new engine has been included into the Cors-Air family.

The Cors-Air M19/Black Magic has been released by JPX Italia/Cors-Air Motors and it will be offered to the flying community very soon.

Following the great success of the Black Devil (Cors-Air M25Y) during the past years, we understood that a smaller and very reliable engine equipped with a centrifugal (centrifical) clutch would be the right response from JPX Italia to the needs of a different category of pilots such as lighter pilots or those interested in a clutch equipped machine.

After almost two years of designing, choosing the right components, redesigning the prototype and final factory testing, JPX Italia built the first series of Corsair M19 engines and sent them to almost all of its dealers around the World for further testing in the field, in the most diversified conditions.

All the independent tests performed by these worldwide known manufacturers (Fly Products, Airfer Paramotores, Paraavis Russia, Ram Aircraft Japan, OU Aerosport Estonia, ALS France and many others) proved that the engine is a definite success. Other tests carried out by importers and dealers as Aerolight USA, Ohio Powered Paragliding, Paratoys, Sky Bike Aviation and Aerocorsair USA, showed that the engine is an extremely reliable, user friendly and smooth running powerplant.

Aerocorsair USA presented this engine at the last Arizona Flying Circus event and tested it publicly. Worldwide known pilots have test flown the engine at this past event (see testimonials)

The similarities between the Black Devil and the new Black Magic engines are pictured below:

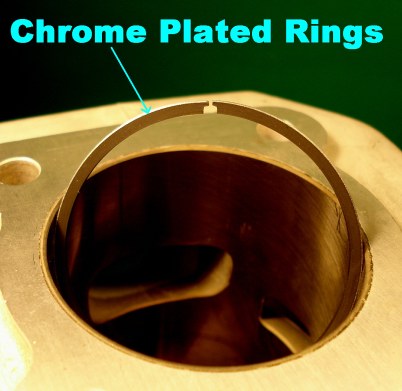

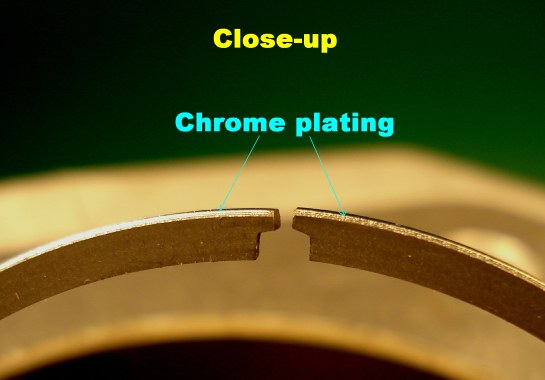

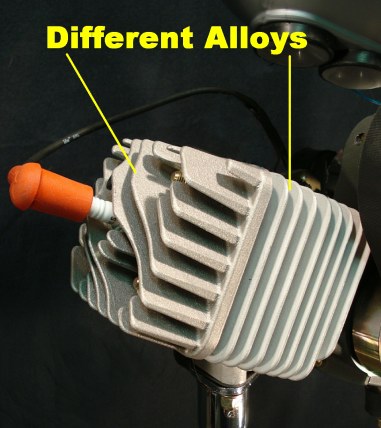

Noted below are the differences between the cylinders and pistons of these engines:

The rings of the Black Magic are Chrome plated for maximum strength.

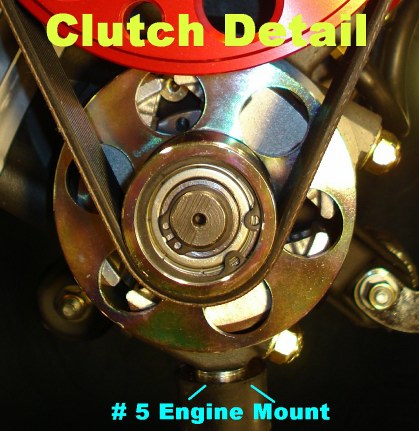

As stated above The Black Magic is a clutch driven engine.

The close-up of this mechanism presented below shows its main components that

JPX Italia has worked for months in designing them. The goal was to achieve the one of the most reliable and long lasting clutches possible.

The "bell" is made of a high quality steel, while the bearings are designed for high RPM.

One very important feature of the Black Magic is that it has no forced cooling which obviously makes this engine simpler and easier to maintain.

The next advantage of the engine is that the distance between the four engine mounts was kept the same as in the Black Devil engine. In other words a paramotor manufacturer can have the same frame for both engines. Conversely, the end user can easily switch from a Black Devil to a Black Magic without the need to fabricate an adaptor plate.

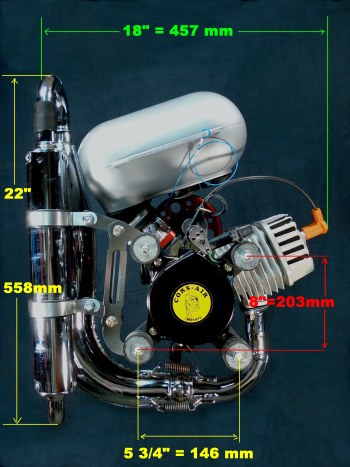

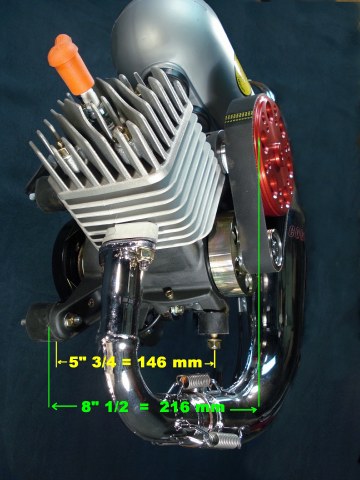

Below, we present other views of the engine along with the conversions inches to millimeters for the convenience of customers around the World.

Back view:

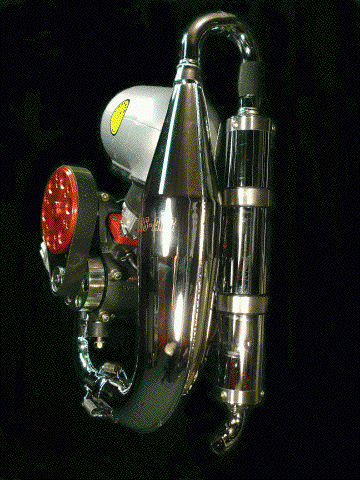

Side view:

The exhaust system is very similar to the bigger version (Black Devil) with the exception of the different manifold and the tuned pipe.

Both engines employ similar mufflers enabling them to be less noisy than similar competing powerplants in their class.

For maximum cooling, the cylinder head is made of a different alloy than the cylinder, just like in the case of the Black Devil (Cors-Air M25Y) The new engines also have an optional cooling shroud tha can be very easily installed on top of the cylinder head.

The Black Magic is fitted with a manual decompressor which makes it a simpler construction.

Cors-Air M19/Black Magic Technical Data:

Engine M19Y

Cycle 2 strokes

Total displacement 119,38 c.c.

Bore 57,5 mm.

Stroke 46 mm.

Weight 9,9 kg without exhaust

Peak RPM 9200

Cooling by free air

Piston of light alloy with 2 piston rings of cast iron S10 chromium-plated

Cylinder silicon light alloy with surfacing of Cermetal (NICASIL)

Head special aluminium alloy

Crankcase Cast alloy G-Al Si 9 UNI 3051

Carburetor membrane

Feeding reed valve on the crankcase

Electronic ignition type TCI

Spark Plug NGK B9ES

Starter manual

Clutch centrifugal

Reduction with Poly V belt

Reduction rate 1:3,12

Continuous normal temperature Max 250 °C

Exhaust pipe tuned

Fuel unleaded gasoline 98 octane and oil at 2,5%

Oil good quality fully synthetic 2 stroke oil mixed with the fuel at 40:1 (2,5%)

Engine suspension: Five rubber mounts (vibration insulators)

MAIN TORQUES Kg.m (Nm)

DECOMPRESSOR 1,9 19

Cylinder head nuts M8 2,2 22

Nuts fo fix half crankcase 2,5 25

Bolts to fix back support base to the crankcase 2,0 20

Ignition magnetic wheel (flywheel) nut